Your position:

Home > Industries > Construction machinery > Mining equipment

Digital hydraulic cantilever tunneling robot

Technical principle:

In the boom type roadheader, the working mechanism of hydraulic cylinder is driven mostly by is valve controlled cylinder mode, namely: pump from the tank to the system power supply circuit, and then by adjusting the valve to control the direction and flow rate of the hydraulic oil to control the hydraulic cylinder displacement size and direction of movement to, in order to promote movement of the working mechanism.

Adopts common hydraulic cylinder, due to the boom type roadheader lifting oil cylinder is a pair of synchronous oil cylinder (the two cylinder movement direction and distance have the same size), the horizontal rotating cylinder is a pair of symmetrical layout of cylinder (the size of the stroke is the same, just the direction of movement of the two cylinder, an elongated, also a corresponding relationship). Therefore, it is necessary to consider the synchronization control, can be in control system added two controller. The two controllers in a group, a total of 2 groups of controller, respectively, to control of boom type roadheader work mechanism of a pair of lifting oil cylinder and a pair of horizontal rotating cylinder. System at work, first of all by the main control computer according to the given section shape and specific size, according to the whole section cutting process of each oil cylinder stroke length needed data, turn into the corresponding controller. After A / D conversion gave servo amplifier and servo valve, and finally translated into corresponding flow of the hydraulic oil cylinder to promote the work, the displacement of the cylinder by the displacement sensor and after a / D conversion sent to the main control computer, complete closed-loop control.

The digital hydraulic cylinder, the system control scheme is shown in figure. With the ordinary hydraulic cylinder electro-hydraulic servo control scheme similar to that in a pair of lifting oil cylinder, can only replace a which a, also a common hydraulic cylinder as the servo cylinder, accept the same controller control; a pair of horizontal rotating cylinder can also use the same method, which will be a replacement for the digital hydraulic cylinder, the oil inlet and also a common cylinder back oil port connected, return oil port corresponding and also a common cylinder into the oil port connected to realize linkage.

The digital hydraulic cylinder, the system control scheme is shown in figure. With the ordinary hydraulic cylinder electro-hydraulic servo control scheme similar to that in a pair of lifting oil cylinder, can only replace a which a, also a common hydraulic cylinder as the servo cylinder, accept the same controller control; a pair of horizontal rotating cylinder can also use the same method, which will be a replacement for the digital hydraulic cylinder, the oil inlet and also a common cylinder back oil port connected, return oil port corresponding and also a common cylinder into the oil port connected to realize linkage.

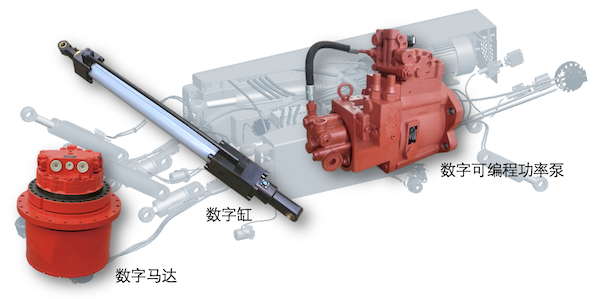

Digital cylinder by electric pulse precise control. The running speed and frequency of the electric pulse corresponding, the displacement and electric pulse corresponding to the number, the control computer to each digital cylinder sends electrical pulses can be precisely controlled all digital cylinder motion characteristics, digital cylinder drives the cutting cutting arm lifting and rotating and the shovel plate cooperative motion can be completed on the working surface of the sectional cutting.

Digital motor by electric pulse precise control. The running speed and frequency of the electric pulse corresponding, the displacement and electric pulse corresponding to the number, the control computer to all digital motor send electrical pulses can be precisely control the motion characteristics of all digital motor, digital motor away crawler can finish walking straight lines, curves.

Digital programmable power pump, is the latest high-end products for the United States Bo mobile equipment energy efficient operation and development. The pump is different from the traditional load sensing pump, and the load sensing pump adopts the negative feedback detection mode to meet the energy saving operation of the working device. But the precision, response and other factors of the sensitive parts and regulation link can not be realized, which is both efficient and energy saving. In the actual use, the two choice is a priority. Digital programming power pump is through digital active feed-forward way to establish pump output flow, the precise coordination of digital hydraulic system flow and pressure requirements, so as to meet the needs of motion device for efficient operation, and realizing the optimization and energy saving effect. Digital programmable power pump for construction machinery, robots and other mobile equipment to achieve high efficiency, energy saving, green work.

The advantages of this control scheme is that the system is composed of closed-loop control to open-loop control, from the original following control changed into active control, and traditional servo control compared with digital cylinder control easier to achieve control of boom type roadheader working mechanism of the whole program, only need to calculate the required control parameter list in the computer, and then turn to the pulse signal after conversion to the corresponding controller can achieve precise control of hydraulic cylinder, so as to improve the quality of the roadway section forming the complex servo control valve; in the traditional export control technology completely changed for a given direct digital control, and the complexity of the system greatly reduce. This is because the digital hydraulic cylinder itself with position closed loop. As a result, the original traditional single closed-loop system variable to dispense with the constant system, an adjustment link, and avoid the traditional servo control in the presence of response lag. Due to the digital cylinder with a higher degree of integration of, appearance and general hydraulic cylinder did not much difference, from the looks of it only oil inlet, oil return port and control cable interface, only need to connected to constant pressure hydraulic oil source, does not require any sensors and other hydraulic components, you can directly accept the controller sends out the pulse signal and reliable work, pulse frequency on behalf of the speed, pulse represents the total number of hydraulic cylinder stroke. Controller can use a dedicated digital hydraulic cylinder controller, you can also use ordinary PLC controller or microcontroller, DSP, etc.. Therefore, the stroke control scheme based on the digital hydraulic cylinder can be used in the work of the cantilever boring machine.